According to the PAS-551 standard on asset management from the British Standards Institute, asset management is defined as: “systematic and coordinated activities and practices through which an organization optimally and sustainably manages its assets and asset systems, their associated performance, risks and expenditures over their life cycles for the purpose of achieving its organizational strategic plan.”

Embodied in this definition, of course, are assets of various types (physical, financial, human, information and intangible), which all contribute to the organizational strategic plan. Best practices dictate that an Asset Management Plan, comprising of three main sub-plans (Operations, Maintenance and Risk) or its equivalent, be developed and implemented for physical assets.

The main focus of this article will be on physical assets, but you will find that some of the risks to asset management identified herein will be shared with the other asset type categories. The author suggests that there are at least five such risks that primarily contribute to an organization’s failure to optimally manage their assets: 1) not knowing what they have; 2) over- or under-maintenance; 3) improper operation; 4) improper risk management; and 5) suboptimized asset management systems.

1) Not knowing what you have

In common manufacturing industry parlance, this is known as the FDH (fat, dumb and happy) approach to asset management. While it might seem intuitively obvious, many organizations either don’t appreciate the need to know with a high level of confidence, the assets that they have or they choose not to take the time to do so. Either way, this has to be the first major step taken towards ensuring that one’s asset management program is effective. Not knowing what one has is tantamount to playing a game of Russian roulette. If an organization is truly serious about their program they will need to take the following steps to establish the proper foundation to build upon:

- Develop a list of all the organization’s assets and verify this list with what is in the field.

- Establish and configure a physical asset hierarchy. ISO 142242 from the International Organization for Standardization (ISO) can be used as reference.

- Develop the criticality evaluation criteria for the business and apply to the verified asset base. This is where the individual assets are linked to how they affect the organizational strategic plan.

- Develop and implement a management of change or configuration management process that will ensure that any future changes to the asset are properly evaluated and recorded.

2) Over- or under-maintenance

During the operational phase of the asset life cycle, there can be a problem of over-maintaining as well as under-maintaining. The key issue regarding over-maintaining typically involves two issues that will make the asset management system ineffective. First, there is generally a significant cost associated with the execution of non-value-added maintenance. In this regard, cost can be loosely used as a guideline since there are well-documented industry benchmarks for maintenance spending that can be followed. Second, the typical organization that can be accused of over-maintaining its assets will most likely be performing intrusive maintenance tasks more frequently. From what we know of how typical failures manifest, this means that there will be additional exposure risk for the business to infant mortality failures and further incurred costs.

The issue of under-maintenance and how it prevents effective asset management is even more clear-cut. Maintenance is often viewed as a business expense open to cutting like any other in order to maximize profits. With these pressures, maintenance departments are constantly struggling with how to balance cost with the performance requirements for the assets such as reliability and uptime. Cost-cutting often wins, however, in the form of delayed proactive maintenance as well as maintenance technicians lacking the necessary skills and tools to perform precise work.

With respect to both the issues of over- and under-maintenance, the author’s recommended approach is, starting with the most critical assets, determine the optimum maintenance requirements of the assets through one of the more rigorous methodologies such as Reliability-Centered Maintenance (RCM). Then, load level the resources (financial and human) required to implement the maintenance plan. Finally, ensure that a training plan is in place to close the skills gap of the persons required for the tasks.

3) Improper operation

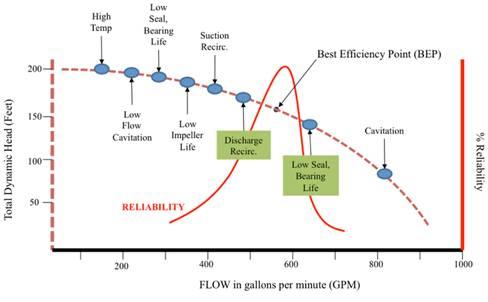

Many organizations suffer first of all from a lack of understanding of the inherent design capabilities of their assets and, secondly, how best to operate within their ranges to optimize the asset life cycle. For some assets, either operating below or above the design range adversely affects the life of the asset. A perfect example of this is the typical centrifugal process pump, as illustrated in the pump curve in Figure 1. Operating on either side of the best efficiency point on the curve is accompanied by a myriad of life-shortening issues. Unfortunately, that is exactly what we do when we choose to speed things up, slow things down or continuously operate assets that were designed to be intermittently run. The best guidance that the author can give with respect to this issue is to: 1) find out how your assets should be run; 2) understand the effects of operating outside of design ranges; and 3) if you can’t operate within the ranges, understand the risks or mitigate the risk (example: resize the impellor to match the operating point).

Figure 1. Pump and Reliability Curve

4) Improper risk management

The basic tenet of best practices asset management dictates that a plan is implemented that not only manages the operation and maintenance of an organization’s assets, but also manages the risks associated with the ownership and use of the assets. Risk, in its most elementary form, is a function of consequences and the likelihood of such an event taking place. Risk management takes place on two major fronts: 1) assessment or identification; and 2) management and controls. Each area, when not done well, is a continued contributor to ineffective asset management. One doesn’t have to stretch the imagination too far to understand this concept. Perform a Google search on the “Bhopal Disaster”3, widely regarded as the world’s worst industrial catastrophe, for an example of unassessed and unmanaged risk. In order to fully manage risk, the author recommends that the following four step model, by ISO, be used:

- Establish context

- Risk assessment: Risk identification, Risk analysis, Risk evaluation

- Risk treatment

- Monitor and review

5) Sub-optimized asset management systems

In recent years, enterprise asset management (EAM) systems have become more popularly used within organizations to manage assets. Most systems have inherent deficiencies that prevent holistic management of all the required areas of the plan. As a result, additional secondary systems are often necessary. That being said, of the features that are available from most EAMs, many organizations are guilty of not fully utilizing them. This generally stems from shortcuts taken during the EAM implementation. The way to fully address this issue is to either do it right the first time or pay more to do it later. The author’s personal preference is the former. This takes planning, resources and treating the implementation as a major change program and not just a project. This is easier said than done, and is often best when supported by the services of change management professionals and asset infrastructure specialists. Apart from the tools (EAM, secondary systems) and technical solutions, we often fail to recognize that our human resources and business processes are important parts of an organization’s asset management system. A lack of due diligence in these areas will also negatively impact the bottom line and should be planned for as well.

Asset management is an integrated approach to optimizing the life cycle of your assets, beginning at conceptual design, through to usage, decommissioning and disposal. By acknowledging and paying attention to these five primary risks to effective asset management, you can put in place plans to mitigate the effects these might have on their program. Note also, that true excellence in asset management performance does not lie only in avoiding the pitfalls, but in turning each and every one of these opportunities to fail into an opportunity to excel.

This article first appeared in the Life Cycle Engineering newsletter RxToday.

References

- PAS 55:2008, Specification for the Optimized Management of Physical Assets, British Standards Institution (BSI), 2008.

- ISO 14224, Petroleum and natural gas industries — Collection and exchange of reliability and maintenance data for equipment, International Organization for Standardization (2005).

- Bhopal Disaster. Trade Environmental Database. TED case studies no. 233, American University, Washington (1 Nov 1997). Link

About the author:

Carl March has a wealth of experience in the areas of maintenance, reliability engineering, systems modeling and design. Carl holds an undergraduate degree in mechanical engineering and a graduate degree in automotive systems engineering. As a reliability subject matter expert at Life Cycle Engineering, his passion and focus is in the transfer of knowledge in RCM, TPM, root cause analysis and Reliability Excellence to clients worldwide seeking to achieve manufacturing distinction. Carl has attained a significant level of professional recognition as a licensed Professional Engineer (PE), a Certified Reliability Engineer (CRE) by the American Society for Quality, and as a Certified Maintenance and Reliability Professional (CMRP) by the Society of Maintenance and Reliability Professionals. You can reach Carl at cmarch@LCE.com. For more information on Life Cycle Engineering, visit www.LCE.com.

Quality of the final product required all operators to wear white gloves. When the techs touched the product, they also donned gloves. One day, Mike was watching Pat perform a corrective task and asked Pat if he could train him to perform those tasks, which they both agreed he was capable of doing. One thing led to another, and line production went up. Pat worked less overtime and did not have to climb the 25 steps to Mike’s work area more than once or twice a day.

Quality of the final product required all operators to wear white gloves. When the techs touched the product, they also donned gloves. One day, Mike was watching Pat perform a corrective task and asked Pat if he could train him to perform those tasks, which they both agreed he was capable of doing. One thing led to another, and line production went up. Pat worked less overtime and did not have to climb the 25 steps to Mike’s work area more than once or twice a day. You are only as strong as your weakest link. While trite, this phrase embodies what manufacturing plants and processing facilities have worked to overcome for years. How do you plan for and prevent broken equipment in your lean machine? Another trite phrase has the answer: The weakest link in a chain is the strongest because it can break it.

You are only as strong as your weakest link. While trite, this phrase embodies what manufacturing plants and processing facilities have worked to overcome for years. How do you plan for and prevent broken equipment in your lean machine? Another trite phrase has the answer: The weakest link in a chain is the strongest because it can break it.